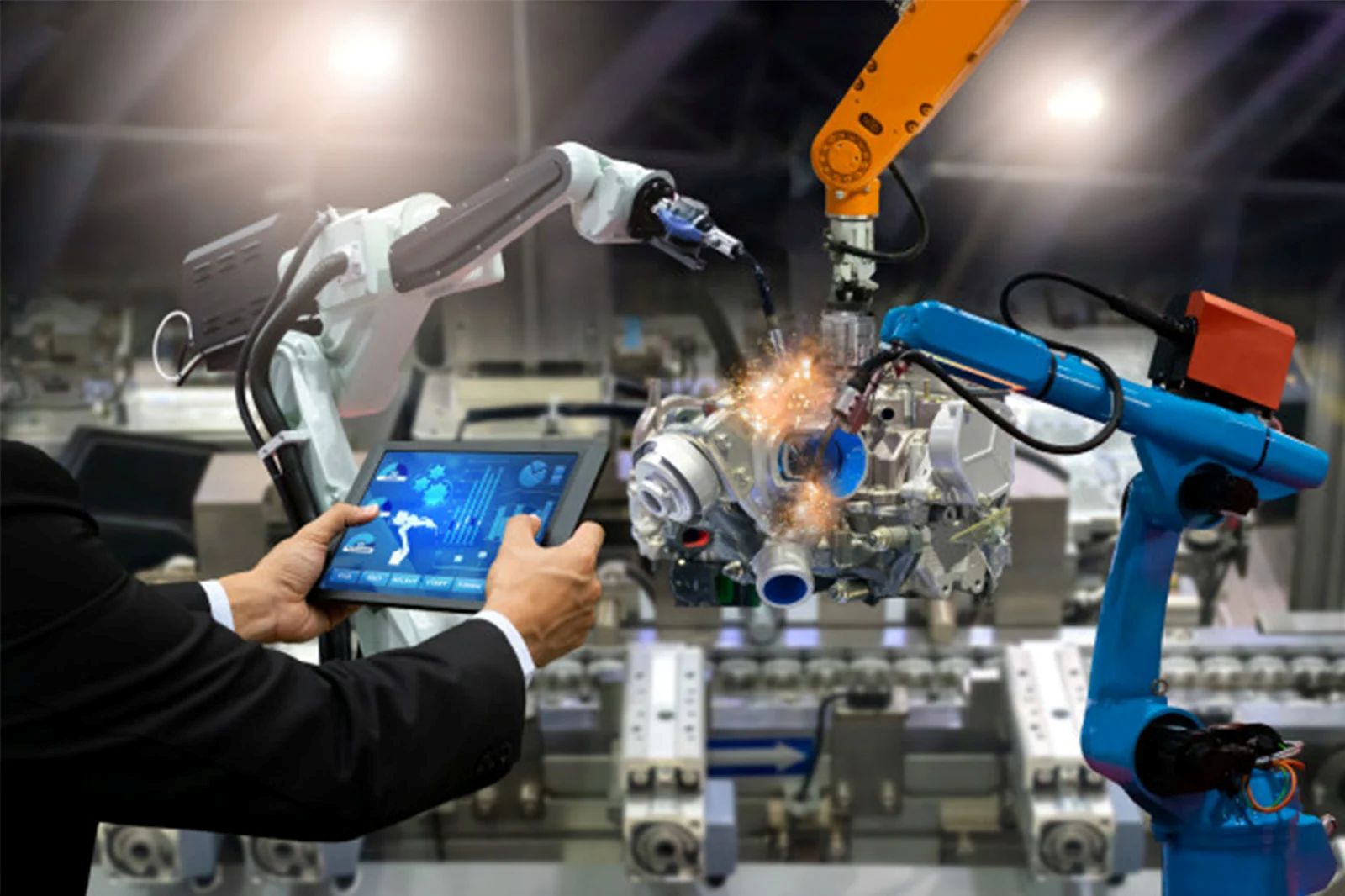

Digital manufacturing is transforming how products are designed, produced, and delivered. But what exactly is it? Digital manufacturing uses computer systems to control and monitor production processes. This approach integrates advanced technologies like 3D printing, robotics, and IoT (Internet of Things) to streamline operations. Digital manufacturing offers numerous benefits, including increased efficiency, reduced waste, and faster time-to-market. Imagine a factory where machines communicate with each other, adjusting in real-time to optimize production. This isn't science fiction; it's happening now. Curious about how this revolution impacts industries and everyday life? Let's dive into 29 fascinating facts about digital manufacturing that will change how you view the future of production.

What is Digital Manufacturing?

Digital manufacturing uses computer systems to control and manage production processes. It integrates advanced technologies to improve efficiency, reduce costs, and enhance product quality. Here are some fascinating facts about this innovative field.

-

Digital Twins: Virtual replicas of physical assets, processes, or systems. They help simulate, predict, and optimize performance in real-time.

-

3D Printing: Also known as additive manufacturing, it creates objects layer by layer, reducing waste and enabling complex designs.

-

IoT Integration: Internet of Things (IoT) devices collect and share data, improving decision-making and operational efficiency.

-

AI and Machine Learning: Artificial intelligence and machine learning algorithms analyze data, predict maintenance needs, and optimize production schedules.

-

Robotics: Robots perform repetitive tasks with precision, increasing productivity and reducing human error.

Benefits of Digital Manufacturing

Digital manufacturing offers numerous advantages, from cost savings to improved product quality. Here are some key benefits.

-

Cost Reduction: Automation and optimization reduce labor and material costs.

-

Enhanced Quality: Real-time monitoring and data analysis ensure consistent product quality.

-

Faster Time-to-Market: Streamlined processes and rapid prototyping accelerate product development.

-

Flexibility: Easily adapt to changes in demand or design with digital tools.

-

Sustainability: Efficient resource use and waste reduction contribute to environmental sustainability.

Technologies Driving Digital Manufacturing

Several cutting-edge technologies power digital manufacturing, transforming traditional production methods.

-

Cloud Computing: Provides scalable storage and computing power, enabling real-time data access and collaboration.

-

Big Data Analytics: Analyzes vast amounts of data to uncover patterns and insights, driving informed decision-making.

-

Augmented Reality (AR): Enhances worker training and maintenance by overlaying digital information onto the physical world.

-

Cyber-Physical Systems: Integrate physical processes with digital control systems, creating smart factories.

-

Blockchain: Ensures secure and transparent supply chain management through decentralized ledgers.

Challenges in Digital Manufacturing

Despite its benefits, digital manufacturing faces several challenges that need addressing.

-

Cybersecurity: Protecting sensitive data and systems from cyber threats is crucial.

-

Skill Gaps: Workforce training and education are needed to keep up with technological advancements.

-

Integration: Seamlessly integrating new technologies with existing systems can be complex.

-

Initial Investment: High upfront costs for digital manufacturing technologies can be a barrier for some companies.

-

Data Management: Handling and analyzing large volumes of data requires robust infrastructure and expertise.

Future of Digital Manufacturing

The future of digital manufacturing looks promising, with continuous advancements and innovations on the horizon.

-

Smart Factories: Fully automated and connected factories will become more common, enhancing efficiency and flexibility.

-

Personalized Production: Customization and on-demand manufacturing will cater to individual customer preferences.

-

Sustainable Practices: Emphasis on eco-friendly production methods and materials will grow.

-

Collaborative Robots: Cobots will work alongside humans, enhancing productivity and safety.

-

Advanced Materials: Development of new materials with superior properties will enable innovative product designs.

Real-World Applications of Digital Manufacturing

Digital manufacturing is already making a significant impact across various industries.

-

Automotive: Streamlined production processes and improved vehicle designs.

-

Healthcare: Customized medical devices and implants through 3D printing.

-

Aerospace: Lightweight, durable components for aircraft and spacecraft.

-

Consumer Goods: Faster product development and personalized offerings for customers.

The Future of Digital Manufacturing

Digital manufacturing is transforming how we create products. From 3D printing to AI-driven design, the possibilities are endless. This technology boosts efficiency, reduces waste, and allows for customization like never before. Companies can now produce complex parts quickly, leading to faster innovation cycles.

Sustainability is another big win. Digital methods often use fewer resources, making them more eco-friendly. Plus, the ability to prototype rapidly means fewer mistakes and less material waste.

As technology advances, expect even more groundbreaking changes. Smart factories and IoT integration will further streamline processes. The future of manufacturing is digital, and it’s already here, reshaping industries and creating new opportunities.

Stay curious and keep an eye on this evolving field. The next big thing in manufacturing might be just around the corner.

Was this page helpful?

Our commitment to delivering trustworthy and engaging content is at the heart of what we do. Each fact on our site is contributed by real users like you, bringing a wealth of diverse insights and information. To ensure the highest standards of accuracy and reliability, our dedicated editors meticulously review each submission. This process guarantees that the facts we share are not only fascinating but also credible. Trust in our commitment to quality and authenticity as you explore and learn with us.